RESEARCH

Agricultural scientists want to know amongst many other things, what is good for Livestock to eat and how to ensure they are healthy and provide optimum quality meat. Hennessy Technology by measuring the yield and quality of the fat and meat tissue of every carcass can provide the scientists with information that supports their research work. To supply if the Livestock and Meat Industry agree, nationally as a whole or in part, meat carcass evaluation data automatically every working day of every year.

The implementation of Hennessy Technology in a meat process plant enables the introduction of an accurate and objectively verified fair payment system for farmer producers. Batch averaging for carcass or primary cut payments can be dispensed with because each carcass or cut can be valued individually. This approach to marketing represents a significant move away from outdated commodity pricing. Feedback from the processors to the producers is based on optimum meat yield and quality. Producers can use this information to fine tune their current feed and breed regimes to become more cost efficient and to develop the Livestock the markets want, by combining the eating quality information that the Hennessy technology provides with the information trace ability technology provides. The sources of the damage to meat eating quality can be identified. Such as stress to Livestock caused by inconsiderate drivers of Livestock carrying vehicles inconsiderate stunning of Livestock.

![]()

Hennessy Technology Ltd provide meat plant operators with a grading system that can be easily integrated into a meat plant that is fully or partially automated. It can also operate as a stand alone building block for basic plant automation.

The Hennessy Grading Probe instrument is easy to use and personnel become competent with it in a very short period of time. Thus Operator maintenance, operator training and acceptance are quickly achieved. Operator performance, power supply performance etc, Operator Uptime and Carcass throughputs automatically logged with meat quality and yield data. Hardware and operational faults are displayed when they occur and are logged for customer feedback at next service interval. The payback time is easily less than 1 year.

The selection of preferred producers and their consistency can be objectively monitored and reviewed on a carcass by carcass basis. Savings in throughput and trimming can be achieved in this way. Continuous quality analysis can also assist in optimizing both chilling regimes and effective use of cold storage space depending on the end use of the carcass.

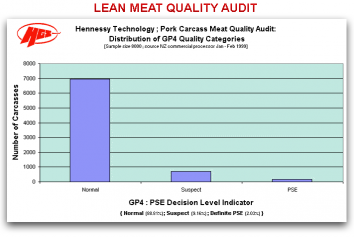

Pre slaughter transport & handling conditions which sometimes induce high levels of stress in an animal can be indirectly monitored through meat quality analysis.View Pork Meat Quality.

![]()

Consistent quality, consistent yields and overall quality discrimination can be used to attract higher premiums from the consumer. Alternatively higher turnover through repeated purchase of substantiated higher quality product.

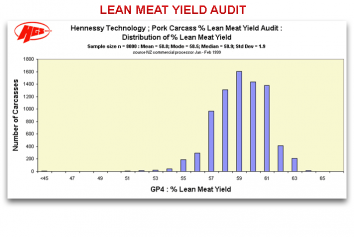

Analysis of Hennessy Probe use on a nationwide basis demonstrates that objective lean meat yield and quality grading with our equipment leads to significant increases in industry earnings.View the Dutch and Swedish Pork industry growth in carcass lean meat yield year on year. Sweden in 1983 was the first country to adopt for national use. Hennessy New Zealand Optical Electronic probe technology to calculate carcass meat yield percentage. The Dutch adopted the use of Hennessy NZ probe technology nationally 6th July 1987. The EU has statutory regulations which require that carcass lean meat yield prediction be the basis for Pig Grading It also has regulations governing the official authorization of certain types of yield grading equipment. Hennessy originated Optical Electronic technology is approved by leading countries Meat Industries worldwide.