GRADING

The Hennessy GP's are renowned worldwide for their very efficient ergonomic design. Making them easy to use and very reliable in long term operation. Basic operator training takes a matter of minutes. GP's can be supplied installed with appropriate software for use in sheep, cattle, pig etc Meat Industries. The same basic principles can be applied for use for deer, ostrich and fish industries.

Eg. Pig carcass grading

The probe can be inserted in one or more specific sites in each carcass. The generated profile(s) are scanned to identify tissue interfaces from which distance measurements are produced. Within selected tissue regions meat quality markers are recorded. The measurements and markers provide the meat quality information and meat yield percentage information needed to provide an objective market description.

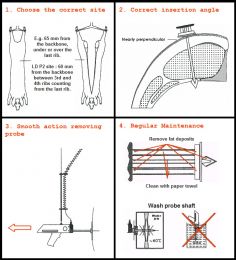

Correct Insertion Sites

The yield and quality prediction equations are based on recording measurements of one or more pre selected sites. The objective quality measurements can be meat & fat thickness, colour, water Holding capacity, intramuscular marbling and tissue structure. That together relate to the meats taste, tenderness and visual presentation.

Correct Insertion Sites

Measurement Principle

Hennessy probe reflectance spectroscopy records profiles of the measurements generated from recording in fractions of millimetres, distances of penetration together with back scattered light signals. Specific optical band widths are selected t provide the optimum information obtainable between and within the various tissues of the species being objectively analysed. The profile of mostly normal quality Pig meat with a little poor quality Pig meat together (PSE) is shown. The Hennessy technology probes principle of reflectance spectroscopy can be easily adapted and utilised to measure liquid density variations and solid material surface finish variations, of numerous substances.

Hennessy probes record ten measurements a millimetre up to 2,000 per second. Typically measuring carcass sites take less than one second.

The Hennessy Gp's technology can be easily integrated into a meat plant's process monitoring data log with either RS232 serial connection or BS4505 current loop protocols. Hennessy System Seven technology will include RS232, RS422, RS485 and LAN connections and exclude the Current loop capability.